Octagonal vs. Ringlock Scaffolding: A Comparative Analysis

In the realm of modular scaffold, ringlock type connection stand as one of the most widely used system in the market. Their widespread adoption can be attributed to their remarkable structural integrity, seamless compatibility, and ease of assembly. Engineered to perfection, ringlock plates provide a secure and reliable connection, empowering workers to construct sturdy and safe scaffolding structures effortlessly.

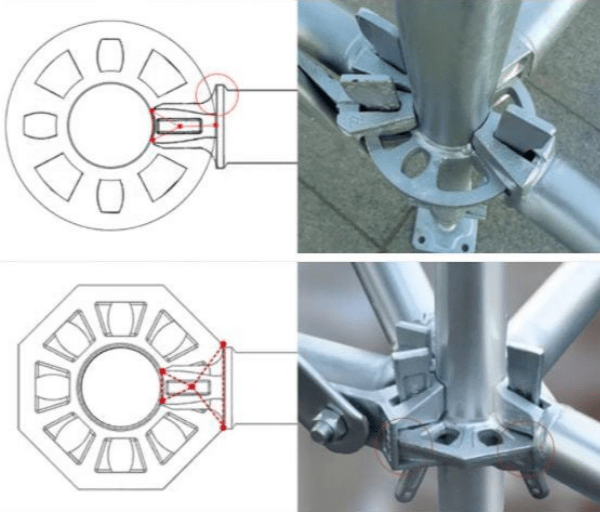

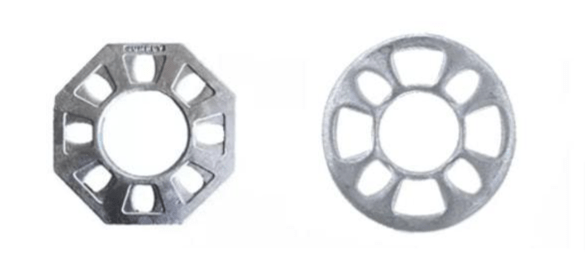

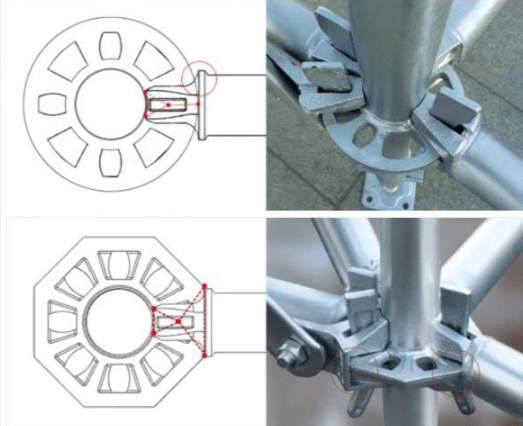

Yet, amidst the dominance of ringlock system, a distinct alternative exists: the octagonal shape node for the connecting ring. This unique variant introduces a fresh perspective to scaffolding assembly, offering versatility and flexibility in design. The octagonal connecting ring, with its innovative geometry, facilitates seamless alignment and integration, allowing for diverse configurations to suit various project requirements.

Discover the Advantages of Octagonal Node Over Ringlock Node Connection!

Today, we unveil the exceptional benefits of Octagonal node, proving why they outshine the traditional Ringlock nodes connection in scaffolding applications.

The biggest feature of the octagonal node is that it has strong torsional resistance and good stability at the joint, hence stiffer joint connection.

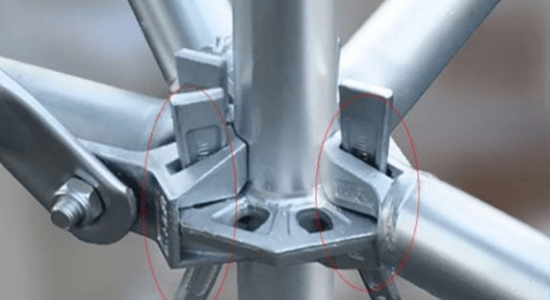

When the horizontal ledger and the vertical standard are connected, the U-shaped groove of the cast ledger end is in contact with the side edge of the octagonal plate. The ledger end is in direct contact with the vertical tube and octagonal side, with the wedge sits perfectly in between. This creates a rigid torsional resistance of the connection between the ledger and the vertical standard. This stiffer connection translates into higher loading capacity of the scaffold in overall.

In addition, the U-shaped groove of the ledger end is designed to sits perfectly in between the octagonal plate, hence reducing the vertical gap movement.

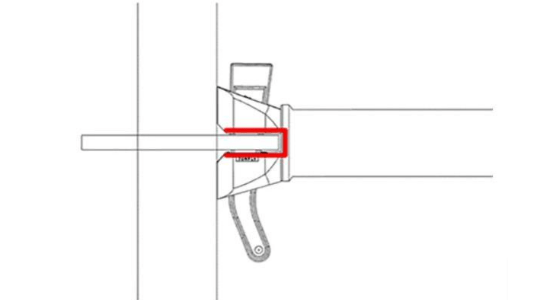

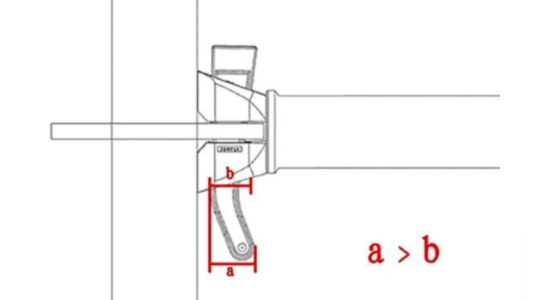

The ledger wedge is designed with a slight bend at the bottom of the wedge. This makes the total width of the wedge is greater than the disc hole length. This will minimise the chances of the wedge from disengaged off the disc accidently.

The difference between octagonal disc and ringlock disc type scaffold.

| Aspects | Octagonal Disc Scaffolding | Ringlock Disc scaffolding |

|---|---|---|

| Nodal Rotational | The ledger end is in direct contact with the vertical tube and the disc octagonal side. This creates a rigid torsional resistance of the connection between the ledger and the vertical standard. | The ledger end is in contact with the ring at only one point of the ringlock disc outer edge. |

| Anti-tripping pin | The ledger wedge is designed with a slight bend at the bottom of the wedge as Anti-Tripping measure which will minimise the chances of the wedge from disengaging from the disc accidently. | Straight wedge. |

| Welded sleeve spigot | The spigot is a sleeve type that is welded to the vertical standard, hence minimising the risk of material loss. | Spigot is bolted to the standard and may be removed after usage. Hence risk of material missing is higher. |

The axes of the vertical standard, the horizontal ledger and the diagonal bracing of the octagonal disc-type scaffold meet at one point. The load flow path is simple and clear; hence produce a stable structure with higher overall bearing capacity. Material and tube section selection make the best use of materials, hence reducinge the amount of steel used which saves materials and cost.

Standard: Every 0.5m on the standard is welded with an octagonal disc plate that can be connected to 8 members at each nodes. One end of the standard is welded with a connecting sleeve to connect to the upper standard.

Ledger: The two ends are welded with cast ledger ends with wedge plate to lock to octagonal disc on the vertical standard.

The octagonal scaffolding system enables workers to set up scaffolding quickly and efficiently, saving valuable time on site. Its superior adaptability allows for greater customization, making it ideal for complex or irregular structures. Additionally, due to its optimise design, the octagonal scaffold provide a more comfortable and safer working environment for laborers, minimizing the risk of accidents and improving overall productivity.

With its exceptional advantages over traditional ringlock scaffolding, octagonal scaffolding is the go-to choice for modern construction projects. Embrace the cutting-edge technology and experience the next level of scaffolding efficiency with octagonal scaffolding today.